-

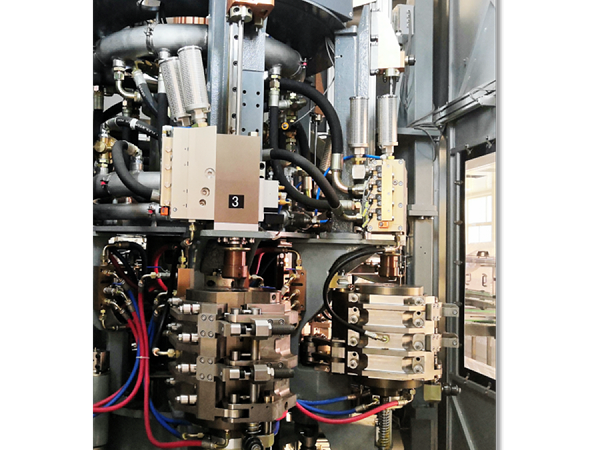

High quality material

Material contact parts are made of stainless steelSUS316And zirconia ceramic material

-

Safety and environmental protection

Zirconia ceramic piston cylinder and rotary valve, high filling precision, no traditional sealing ring, safety and health, zero pollution to materials

-

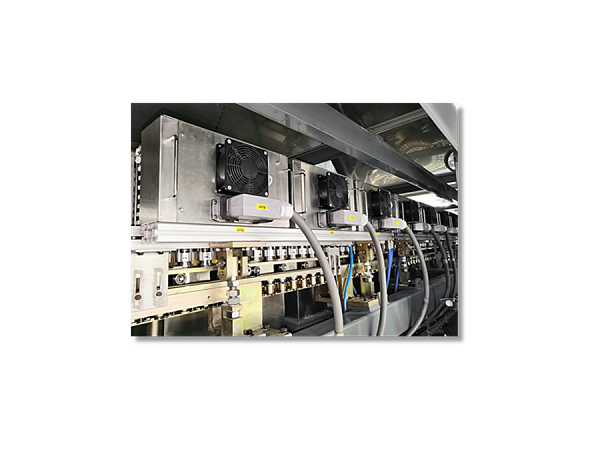

One key operation

Adopt motion controller andHMIMan-machine operation interface, you can call parameters in the operation interface

-

Accurate positioning

Adopt robot absolute value servo system, high filling precision, accurate positioning

-

Production efficiency

Filling action is brisk, so that there is bottle filling, high production efficiency

-

Strong adaptability

Both bottle mouth and submerge segmental filling mode, suitable for the production of a variety of materials

-

Clean and convenient

Material contact parts disassembly without auxiliary tools, easy cleaning without dead Angle

-

Flexible job

Mobile configuration, convenient combination of multiple sets, flexible operation, effective and reasonable use of space

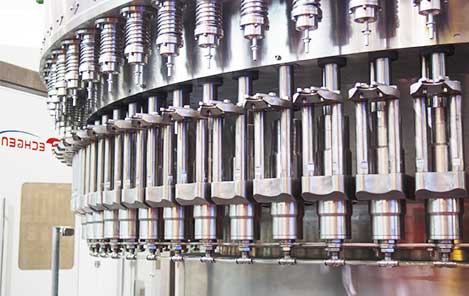

Mobile tracking capping machine

Mobile tracking capping machine  Tracking capping machine

Tracking capping machine