-

Agile and convenient

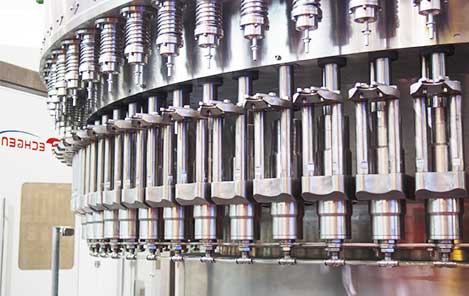

Gas controlled isobaric valve gas filling, gas controlled isobaric valve control is more flexible and convenient exhaust mode can adopt pulse exhaust, filling process time, convenient adjustment.

-

High quality material

The filling valve and its assembly consist of304High quality stainless steel, very high finish, easy to discharge and barrier-free laminar flow.

-

Automatic stabilization

The material cylinder is equipped with a liquid level sensor, which can automatically stabilize the liquid level in the material cylinder by controlling the regulating valve on the material feeding pipe.

-

Ensure the quality

The cylinder, filling valve and other parts in contact with the material are used304High quality stainless steel to ensure product quality.

-

Stable and reliable

5. The base of the equipment is made of carbon steel with excellent external application304Stainless steel, integral welding processing, with enough rigidity and ensure processing assembly accuracy and machine movement stability.

-

The transmission system

The combination of reducer motor and open gear drive has the advantages of simple structure, stable operation and convenient maintenance.

-

Overload protection

Bottle feeding system is composed of bottle feeding screw and star wheel guard plate. The lower part of star wheel is equipped with overload protection device to prevent the equipment parts from being damaged when the bottle is overloaded.

-

Maintenance is convenient

Equipped with centralized lubrication system, convenient maintenance.