-

High quality material

Material contact parts are made of stainless steelSUS316L;

-

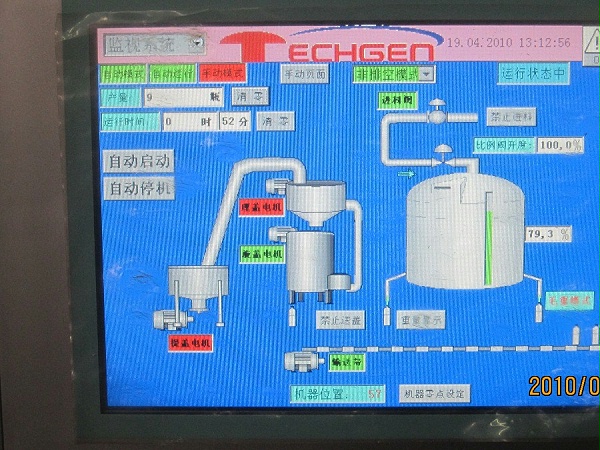

One key operation

2, using motion controller andHMIMan-machine operation interface, parameters can be called by one key in the operation interface;

-

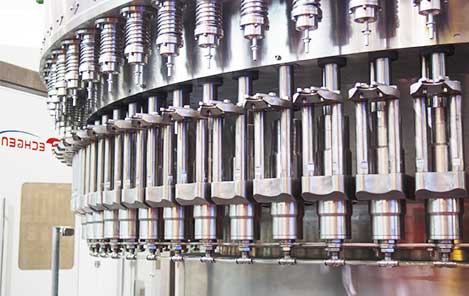

No bottle no filling

The bottle feeding system adopts photoelectric detection, so that there is bottle filling, no bottle filling;

-

To adapt to the diverse

Filling machine has lifting adjustment device, suitable for different bottle filling.

-

Cleaning without dead Angle

Material tank with cleaning device, easy to clean without dead Angle, suitable for a variety of material production;